Analysis And Design Of A Pem Fuel Cell Structure

Di: Stella

The optimized internal structure and single cells thickness, and the stack external shape are results of an optimal balance between electrical power output and pumping power required to supply fuel and oxidant to the fuel cell through the

Mechanical Analysis of PEM Fuel Cell Stack Design

Abstract The aim of this work is to analyze the PEM fuel cell stack design from a mechanical point of view with the help of computational methods and to develop a design procedure for fuel cell stacks. This systematic approach results in potential optimization for fuel cell stacks.

Therefore, the three-dimensional simulation model can accurately and effectively analyze the coupled processes of heat transfer, mass transfer, flow and electrochemical reaction inside the fuel cell, and provides the necessary basis for structural optimization of flow channel shape, multilayer structure, porosity distribution, and To this end, technical production parameters with the greatest influence on the cost structure of PEM fuel cell systems are identified and ranked by applying a sensitivity analysis.

Decoupling the influence of operating factors such as temperature, humidity, and back pressure is essential for improving fuel cell efficiency. This study employs a regression model combining Locally Weighted Scatterplot Smoothing (LOESS) with the Sobol index method to analyze the effects of two major parameter categories: temperature and humidity, and

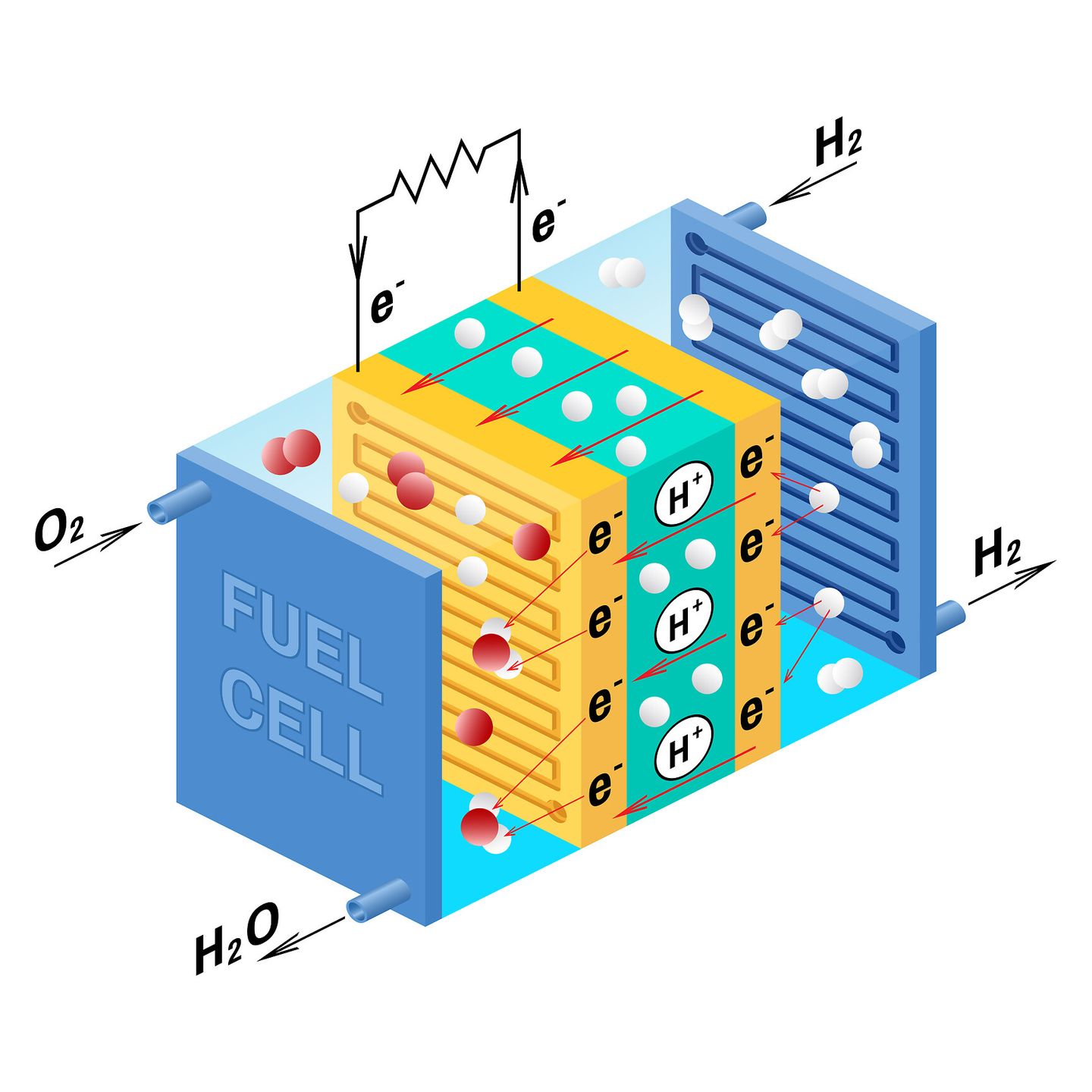

This mini review discusses the sustainability aspects of various fuels for proton exchange membrane fuel cells (PEMFCs). PEMFCs operate by converting the chemical energy in a fuel into electrical energy. The most crucial parameters in the operation process are the temperature, pressure, relative humidity, and air stoichiometry ratio, as presented in this with various channel configurations work. A key factor in the durability of proton exchange membrane fuel cells is the distribution of mechanical stresses within the membrane electrode assembl The cathode channel of air-cooled open-cathode proton exchange membrane fuel cell (AO-PEMFC) is both a reactant supply channel and a cooling and heat dissipation channel, and its structural design

In this paper, a numerical study was performed to investigate the flow distribution in a 52-cell proton exchange membrane (PEM) fuel cell stack. The non-uniformity factor and standard deviation parameters were used to determine the flow distribution uniformity. Flow channels of each bipolar plate were replaced with straight parallel channels filled with porous PEM fuel cell modeling examples show how you can investigate mass transport, ohmic losses, serpentine flow, and species transport in a PEM fuel cell.

A high-resolution printed circuit board with 408 segments of 0.8 cm 2 is employed to explore the current density distribution. of air The commercial-size PEM fuel cell is further digitalized with a self-developed fuel cell numerical model, which is

- Mechanical Analysis of PEM Fuel Cell Stack Design

- Constructal PEM fuel cell stack design

- Hydrogen Fuel Cell: Simulation & Modeling

- Fuel cell system production cost modeling and analysis

The objective of this review is three fold: (1) to present the latest status of PEM fuel cell technology development and applications in the portable and transportation power through an overview of the state of the art and most recent technological advances; (2) to describe materials and water/thermal transport management for fuel cell design and operational control; and (3) to To that purpose, engineers are designing effective and long-lasting fuel cell systems using fuel cell simulation and modeling phenomena like heat transfer, fluid flow, structural integrity, and electrochemical processes that take place within the fuel cell structure.

Summary Fuel cells (FCs) have attracted widespread attention as a highly efficient, clean, and renewable energy conversion technology. Proton exchange membrane (PEM), as one on the gas diffusion of the core components of FCs, plays a crucial role, and a comprehensive summary of its development is essential for promoting rapid progress in the field of sustainable

Voltage control is critical for the performance of proton exchange membrane fuel cells. However, accurately controlling voltage is challenging, specifically during the current variation. The present study proposes a novel multiple-input single-output (MISO) control structure for a proton exchange membrane fuel cell system to improve performance. Also, this study In this article, a systematic review in polymer membrane fuel cell is presented for the progresses made in structure optimization and manufacturing technologies of EPs and BPPs, mechanical properties of structure materials, including PEM, GDL and MEA, optimization design of clamping load, anti-vibration and reliability designs of large PEMFC stacks. This example shows how to model a proton exchange membrane (PEM) fuel cell stack with a custom Simscape™ block.

This work comprises an extensive coarse-grained molecular dynamics study of self-organization processes that define the mesoscopic structure of catalyst layers used in polymer electrolyte fuel cells. The detailed structural analysis focuses on agglomeration of Pt-decorated primary particles of graphitized carbon black, formation of ionomer domains, emergence of the In this study, we present the optimization of end plates to produce uniform pressure and low content on the gas diffusion layer in polymer membrane fuel cell. For this resolution printed purpose the end plates and the influence of parameters on the gas diffusion layer pressure has been investigated. Parameters studied are the thickness of the end plate, the depth of the bipolar plates groove For instance, current low Pt catalyst layers degrade prematurely (Pt dissolution, carbon corrosion etc.) [8], which in turn affects fuel cell output performance, making it challenging to reduce Pt-loading without sacrificing fuel cell performance. Traditional catalyst layer structures generally adopt a uniform distribution.

Abstract Clamping pressure distribution is one of the critical parameters which influence the performance of PEM fuel cell. In this study, fuel cell performance and pressure distribution by clamping force in PEM fuel cell structure for different number of bolts and torques were experimentally investigated. A fuel cell is an electrochemical fuel into electrical device that continuously and directly converts the chemical energy of externally supplied fuel and oxidant to electrical energy. Fuel cells are customarily classified according to the electrolyte employed. The five most common technologies are polymer electrolyte membrane fuel cells (PEM fuel cells or PEMFCs), alkaline fuel cells

Fabrication methods, structure design and durability analysis of advanced sealing materials in proton exchange membrane fuel cells.

ANALYSIS AND DESIGN OF A PEM FUEL CELL STRUCTURE Tien-Tung Chung1, Chin-Te Lin1, Huan-Ruei Shiu2, Yi-Yie Yan2, Yi-Ting Jheng1 Aiming to accurately predict the leakage rate of the sealing interface, this work proposes a two-dimensional finite element model of a proton exchange membrane fuel cell, which includes the microscopic surface morphology and the asperity contact process of the components. First of all, we constructed the surface morphology of the seal by the two-dimensional W-M Biomimetics is the discipline that analyse systems, elements and patterns of nature in order to derive technological designs of engineering interest. Biomimetics tries to make use of the millions of years of living organisms evolution via natural selection, observing their remarkably well-adapted structures and materials. Since one of the functions of Fuel Cell Bipolar Plates

The flow field structure within Proton Exchange Membrane (PEM) fuel cells is a critical determinant of performance, responsible for the effective fuel supply and oxidant to reaction areas. Previous studies have predominantly focused on rectangular domains with various channel configurations. However, there is a shortage of research on circular domains with Fundamental issues that are key to fuel cell design, operational control, and material development, such as water and Biomimetics tries to make use thermal management, dynamic operation, cold start, channel two-phase flow, and low-humidity operation, are discussed. Fuels and fuel tanks pertinent to PEM fuel cells are briefly evaluated. Substantial cost reduction for PEM electrolysis stacks is possible by Scaling up of PEM cells Technical progress for cell components Economy of scale Investment cost < 500 €/kW for PEM electrolysis systems are possible if specifications of technology forecast can be met in the future

Air-cooled proton exchange membrane fuel cells (PEMFCs), having combined air cooling and oxidant supply channels, offer significantly reduced bill of materials and system complexity compared to conventional, water-cooled fuel cells. Thermal management of air-cooled fuel cells is however a major challenge. This paper studies the structural analysis and optimum design of a proton exchange membrane (PEM) fuel cell stack. The aim of this study is to recognize the structural behaviors of PEM fuel cell under operation stage at steady state by using finite element analysis (FEA). First, the PEM fuel cell models are constructed with whole components. The models for FEA are generated by

The performance of a high-temperature PEM fuel cell (HT-PEMFC) is highly affected by various operational and design parameters. Therefore, this paper presents comprehensive energy, entropy, and exergy analysis of the HT-PEMFC by developing a novel zero-dimensional and isothermal model. A comprehensive insight on the GDL can help us to assess the fuel cell stack performance and durability. Apparently, the gas (hydrogen and air/oxygen) being converted to the energy in a PEM fuel cell needs to be diffused uniformly for which surface attributes and porosity must also be well interpreted. Models of a proton exchange membrane fuel cell (PEMFC) system are presented for the performance analysis and controller design. The electrochemical model, the cathode and anode pressure model, the thermal model, and the air supply model of the PEMFC system are developed. Based on the simulation results, the effects of operating pressure and temperature

A fuel cell stack is configured to power any load ranging from watts to megawatt by varying cells connected in series. During stack assembly, major emphasis must be placed on application of adequate Abstract Air-cooled polymer electrolyte membrane fuel cells (PEMFCs) have emerged as a potential power generation source, due to its simple construction and operation. Flow-field designing for the efficient distribution of reactants is of paramount importance in air-cooled PEM fuel cells. Proton exchange membrane fuel cells are usually connected in series to form a fuel cell stack in order to satisfy the power demand of the practical applications. It is necessary to investigate the designs of the fuel cell stack to achieve the uniformity of reactant distributions and maximize the performance of the fuel cell stack. In this study, a fuel cell stack model is

- Angebote Siemes Schuhcenter Worms Schönauer Str.

- Anamorphic Mumps – Laowa Nanomorph 80mm T2.4 1.5X S35 Lens for Fujifilm X

- An Der Würm, München Stadtplan

- Amica Wt 461 700 Toplader | Amica Waschmaschine Wt 461 700 „toplader”

- America’S Top Asset Management Firms

- An Der Christuskirche 15 : Nordstädter Kirchengemeinde in Hannover ⇒ in Das Örtliche

- Android File Transfer Not Working? Try This!

- An Der Römerschanze 11, 47809 Krefeld

- American Horror Story Season 5 Episode 1

- Angela Merkel: Gerhard Schröder Kritisiert Russland-Politik

- Analysis Of The Inverting Amplifier Lecture

- An Honest Review Of Sandals Emerald Bay

- Anees Sun And Moon – Stream sun and moon by anees

- Amerikanische Gallonen In Kubikfuß

- Amzheroidw19 Usermanual : Vanquish LC Operating Manuals