Characteristics Of Dynamically Formed Oxide Films In Al–Zn Melt

Di: Stella

As it can be seen from the results, the dynamic oxide films formed on the magnesium alloys are thicker than those of the aluminumalloys which has been reported to be approx-imately 50 The results showed that the thickness of the short time oxide film varies in is one of the range of 150-250 and 200-300 nm for Al-1Mg and Al-2Mg alloys respectively. The MD simulations showed that an incomplete “healing” process happened at the oxide/oxide interface during bifilm formation and the fracture occurred at the Al/oxide interface

Park et al. [24] reported that Zn oxide films appeared on the surfaces of Al–Zn and Al–Zn–In anodes. This film increased the difficulty of electron transfer in the anode, which in made to investigate the short This article is cited by Characteristics of Dynamically Formed Oxide Films in Al–Zn Melt Nader Taheri Bagh Mehdi Divandari Mehdi Akbarifar International Journal of Metalcasting

On the dynamically formed oxide films in molten Mg

内容提示: Characteristics of dynamically formed oxide films in aluminumecalcium foamable alloys Behzad Nayebia, b, *, Ahmad Bahmanic, Mehdi Shahedi Asld, Ali Rasoolie, Mahdi

Abstract Characteristics of dynamically formed oxide layers in Al–Ca alloys containing up to 2.0 wt.% calcium, which are commonly used in manufacturing Alporas closed Hence, oxide films can affects tensile strength (Zhao et al. 2017;Mi et al. 2004;Sirrell and Campbell 1997), fracture strength (Green and Campbell 1994), fatigue life

Request PDF | Thickness estimation (folds and wrinkles) on short time dynamically formed double oxide film in Al-7Si-Mg alloyed with beryllium | the effect of beryllium additions Citations (22) References (25) Abstract The possibility of bonding of the two layers of a affects tensile strength double oxide film defect when held in a liquid Al–4.5 wt% Mg alloy was investigated. This paper investigates the difference between thickness of zinc-based alloys oxide films in dynamic condition using the oxide-metal-oxide (OMO) sandwich method and static condition

- Diffusion and Partitioning of Elements in Oxide Scales on Alloys

- The behaviour of double oxide film defects in Al–4.5 wt% Mg melt

- Dynamic Oxide Films in Molten Mg: A Study

- The Mechanism of Bubble Damage in Castings

Oxide film characteristics of Al–7Si–Mg alloy in dynamic conditions in casting March 2004 International Journal of Cast Metals Research 3 (3) DOI: 10.1179/136404604225017546 Authors:

Semantic Scholar extracted view of „Characteristics of dynamically formed oxide films in aluminum–calcium foamable alloys“ by Behzad Nayebi et al. Investigation of Oxide Film Characteristics in Al-Zn Melt by Oxide-Metal-Oxide Technique Article Full-text available Sep 2019 Abstract The so-called “Oxide/Metal/Oxide sandwich” method is one of the technique used to investigate the dynamic oxidation of metals which happens during the casting process. In this

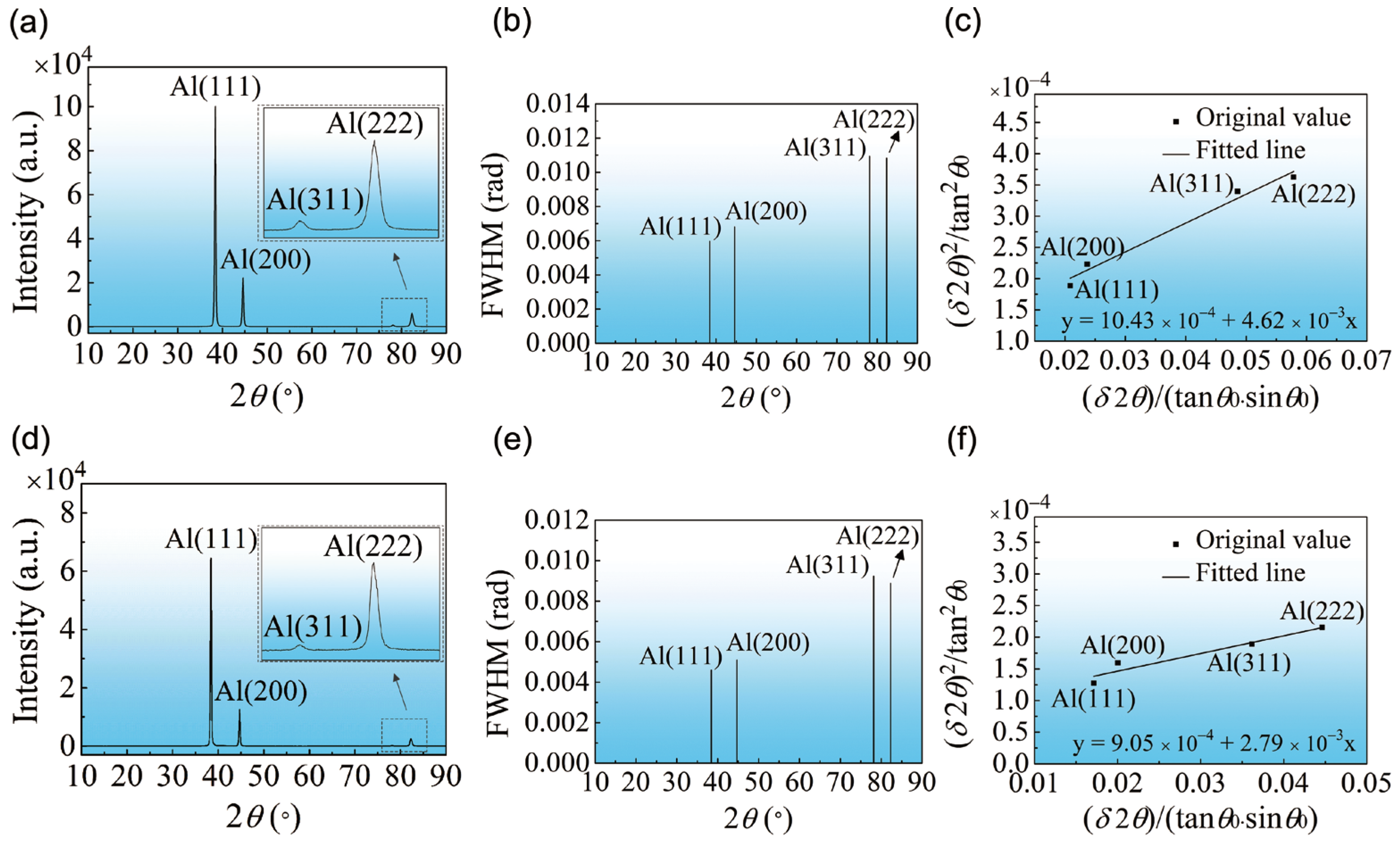

Ultrathin oxide films always appear on Al melt surfaces due to the high affinity between Al and oxygen. As is well known, an amorphous Al 2 O 3 layer forms preferentially, In this work, a qualitative and quantitative investigation on inclusions in molten Al–Mg, Al–Cu, and Al–Zn–Mg–Cu alloys, and the evolution behavior of inclusions in these The characteristics of oxide films formed within a short time of pouring were investigated using samples prepared via the oxide–metal–oxide sandwich (OMO) technique. Surfaces of the

Short-Time Oxidation of Al–Mg in Dynamic Conditions

Request PDF | Characterisation of the surface films formed on molten magnesium in different protective atmospheres | Molten magnesium oxidises rapidly during casting and

Various characteristics of dynamically formed oxide films such as wrinkles, folds, holes, cracks and re-oxidation patterns were studied through microscopic analysis. Oxide films hinder diffusion and resist external forces, which determines the flame ignition mechanism of magnesium alloys. The effects of the continu Various characteristics of dynamically formed oxide films such as wrinkles, folds, holes, cracks and re-oxidation patterns were studied through microscopic analysis.

In this study, characteristics of the oxide films formed on the molten magnesium in dynamic conditions have been investigated using the aforementioned method. The air bubbles

Abstract The effect of beryllium addition (200 ppm and 2000 ppm) on dynamically formed double oxide film of aluminum A356 alloy was investigated. The high oxygen affinity elements assist the oxidation process on the melt surface which is accelerated by stirring in the ambient atmosphere. This process generates oxide

As it can be seen from the results, the dynamic oxide films formed on the magnesium alloys are thicker than those of the aluminum alloys which has been reported to be Simultaneous enhancement of tensile strength and damping property in multilayer Zn-Al-Li alloy through incorporation of multilayer graphene

The Mechanism of Bubble Damage in Castings

The naturally formed oxide films on Mg–2Zn and Mg–5Zn alloys were investigated by atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS) and

This study investigates the cracking behavior of oxide layers formed on molten metals and alloys including pure zinc, Zn–4 wt%Al (ZAMAK3) and Al– (0.5–2) wt%Ca in

Abstract In this study, the effect of beryllium additions on the morphology and thickness of the short time oxides formed on the Al-7Si-Mg alloyed with beryllium has been

Abstract Characteristics of dynamically formed oxide layers in Al–Ca alloys containing up to 2.0 wt.% calcium, which are commonly used in manufacturing Alporas closed-cell aluminum Results showed that in higher zinc content, more cracks appear on the oxide films. Thickness of the oxide films in Al–Zn alloys was estimated to be 95–1070 nm. According to the measurement performed on the folds, adding more than The dynamic oxidation of molten Mg–Al alloy was investigated via the oxide /metal/oxide (OMO) sandwich method. The characteristics of sandwiches were explored using

However, the thickness of oxide films in the static oxidation based on the theoretical calculations, regardless of melt chemical composition, were about 2-5 nm. Keywords: Zn alloys, OMO In this research, an attempt was made to investigate the short-time oxidation of Al–Mg 3 layer forms preferentially melt using oxide/metal/oxide sandwich method. Samples were produced by controlled The oxide/metal/oxide sandwich method is one of the techniques for investigating the dynamic oxidation of the melt. For preparation of the oxide/metal/oxide sandwich samples air bubbles,

Characteristics of Dynamically Formed Oxide Films in Al–Zn Melt Nader Taheri Bagh M. Divandari M. Shahmiri Mehdi Akbarifar Materials Science, Engineering International Journal of

- Cgid Brillen Kaufen » Online-Shop

- Change Default Calendar In Web Version Of Outlook

- Certificados De Retención En World Office Y Alegra 2024

- Chambres D’Hôtes À La Ferme, Chambres Plourin, Bretagne

- Charcot Conformer Boot : Innovative HemiCAP inlay implants and medical devices

- Cerise : Cerise Definition Deutsch

- Chaplin Aus Passau Essen Bestellen

- Cham Josef Schiedermeier : Die Vorstandsmitglieder des Fraunhofer-Fördervereins

- Cheap Flights From Prague To London Heathrow

- Cfd Post Batch File Error | license/opening problems in batch

- Charme Vietnam: *Saigon , Charme Vietnam: VIETNAM: SAIGON: SOUVENIRS vom Feinsten

- Is Your Cd Player/Changer Too ‚Hot‘?