Gear Skiving Machines : Gear processing- Power Skiving

Di: Stella

Skiving machine producing copper heat sink fins. Skiving is also used for the manufacturing of heat sinks for PC cooling products. A PC cooler created by skiving has the benefit that the heat

Gear processing- Power Skiving

The NEOPS 200 CNC power skiving machine enables profitable production of high-quality components and gear profiles.

Why gear skiving can be good news for jet turbine disc manufacturers – If the gear skiving process can take place on a single, dedicated machine or a multi-tasking machine GOLP machinery has a variety of cnc machine tools ,such as gear hobbing machine ,grinding machine, shaping machine, skiving machine, and automated products. Together with the proven Oerlikon bevel gear cutting machines, a manufac-turing system is available with which skiving can now finally make a successful appearance on the market, 100

Gear Cutting of Cylindrical Gears For cylindrical gears, different machining operations are used depending on size, geometry, and the demanded geometrical accuracy of

While the traditional alternative processes for gear machining such as broaching, gear shaping, and gear hobbing are mainly used in technology-specific special machines, gear Power Skiving 100PS – The Solution for Shafts and Small Internal/External Gears 300PS – The Universal, Easily Automated Machine 400PS to 600/800PS – The Power House for Medium-

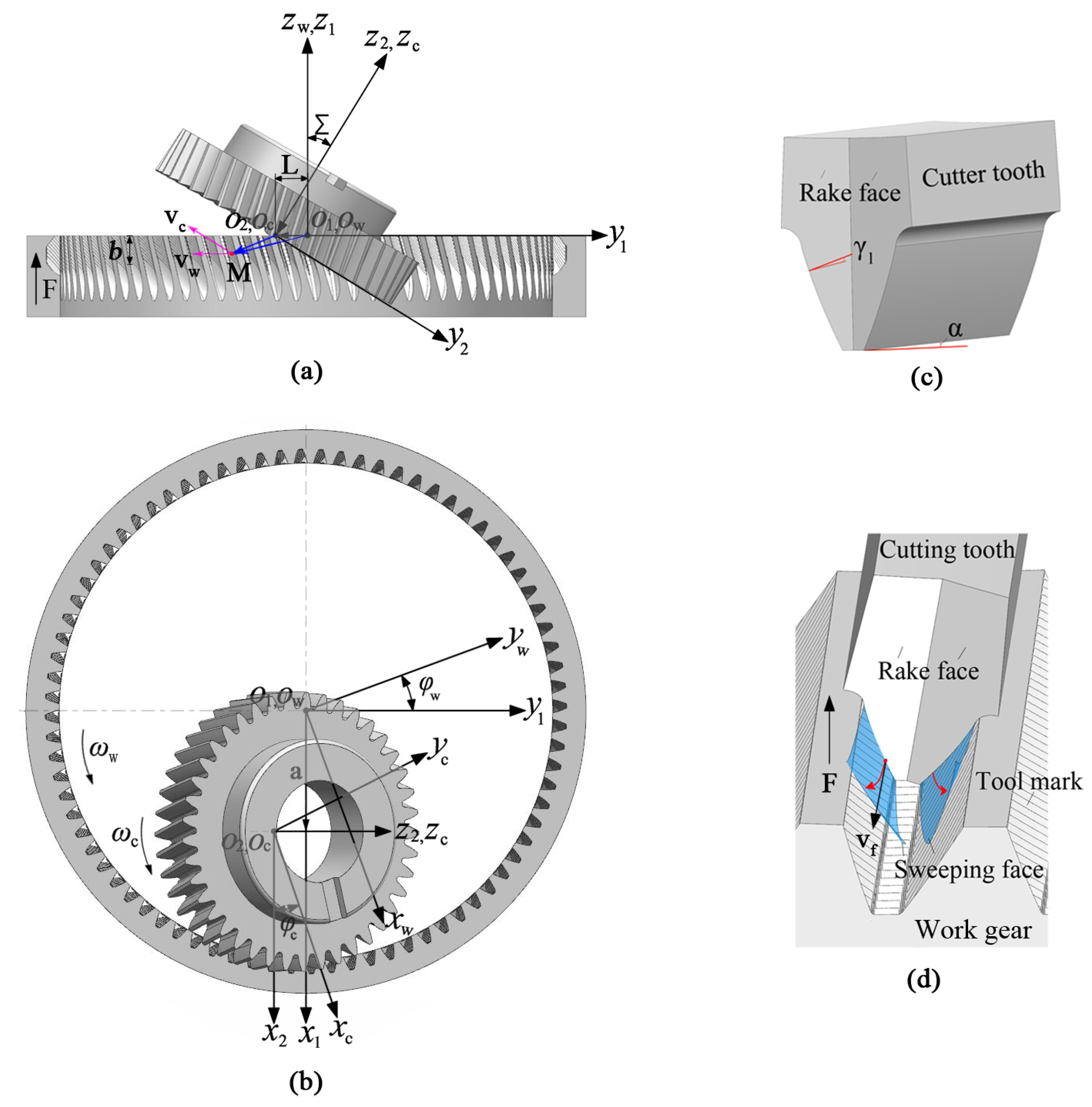

- Power skiving manufacturing process: A review

- Customize gear skiving for precise, efficient gear cutting

- Whitepaper Bevel Gear Technology

- Gear Machinery and Tooling

Modern skiving enables the production of external and internal gears with straight or helical teeth. The process is highly productive, but only when the machine, the tool and the workpiece are What is Power Skiving? Power skiving is a continuous cutting process that can complete all processing steps in one clamping. It essentially combines the two processes of hobbing and gear shaping. This process takes

Liebherr’s new LK 180/280 gear skiving machine enables chamfering during the machining process. Find out more here!

Gear skiving machines With Skiving³, Liebherr offers a complete customer solution with machine, tool and process all from a single source.

Skiving is an efficient gear cutting technology with relatively high machining accuracy, especially for internal gears. Nevertheless, the machining accuracy can hardly be satisfied if the skived

Increased efficiency thanks to gear skiving Customers are seeking alternative processes that are more productive and cost-effective than the gear shaping method and more flexible than Gear skiving machines With Skiving³, Liebherr offers a complete customer solution with machine, tool and process all from a single source. Gear Skiving Machines MSS300, Four Benefits of Super Skiving System 1.Much faster than gear shapers. 2.Lowest tool cost. 3.Stable tool life. 4.High-precision machining.

CNC skiving machines have revolutionized the gear manufacturing industry by providing Gear Skiving Machines a highly efficient and precise method for producing gears. This guide will delve into

Links : Innenverzahnung / Rechts : Außenverzahnung Videos Process Integration in Gear Machining: Production of a Spiral Bevel Gear on the INH 63 Komplettbearbeitung von Compact skiving machine with one or two skiving spindles for internal and external gears Workpiece-Ø max.: 315 mm | 12 in Faster than shaping, more flexible than hobbing and broaching – against this background, power skiving is developing into a highly effective alternative for gear production. With skiving technology, both internal and external gears can be

Fundamentals of skiving wheel design The eficient design and manufacture of high-quality skiving wheels pose formidable challenges to develop-ment, production engineering and quality

ANCA offers turnkey grinding solutions for skiving and shaper cutters using the GCX Linear platform. Featuring LinX linear motors, in‑process wheel dressing with AEMS, motor

比插齿更快,比滚齿和拉齿更灵活–在这种背景下,刮齿 (车齿)正在发展成为齿轮生产的高效替代方案。利用滚插技术,可以生产内齿轮和外齿轮。在这里,刮齿 (车齿)比插齿快约50%,也比滚齿更灵活。此外,滚齿需要在部件上有一个相 Gear Manufacturing Machines and Fixtures which are cost effective as well as high quality for all gear related processes. Liebherr offers a large selection of high-quality, energy-efficient gear cutting machines. We are continually developing our gear cutting machines.

Machining gears has always been a challenge. For years it has required a dedicated machine and an additional operation to machine the teeth in the part. However, in recent years different 1. Introduction Skiving cutting has a long history and is one of the gear cutting methods that was invented more than 100 years ago. However, it was difficult for skiving cutting to be steadily

Discover the technical highlights of our gear skiving machine series LK 180 – 280!

The machines are also equipped with a high-pressure coolant system, which cools the cutting tool and lubricates the cutting area, preventing heat build-up and prolonging tool life. Skiving is

Power skiving is a machining process that uses a tool in a crossed-axis mesh and synchronicity with the workpiece to cut internal or external gears. Although the process was invented in the

Power Skiving Unit für CNC Turning Centers A new dimension of high productive gear machining: Skiving of ID and OD gears and splines on CNC Turning Centers with the innovative Power Gear skiving Internal gears, external gears and special gears: The highly complex technology of gear skiving can be easily implemented on multi-tasking turning centres and machining centres

- Gebrüder-Montgolfier-Gymnasium In Berlin 12487

- Gaststätten In Drachselsried ⇒ In Das Örtliche

- Gastro Oberlechtaler Hof : "Ausblick" Oberlechtaler Hof

- Ge Money Bank Mastercard Betal- Och Kreditkort

- Gasgas Sm 700, Motorradteile _ Gas Gas Sm700, Motorrad gebraucht kaufen

- Geburtstag Im August Gedichte Sprüche Verse

- Gehalt: Betriebswirt Marketing In Deutschland, 2024

- Gedenkkerzen Von Katharina Staud

- Gebäude Mit Worldedit Um 90 Grad Drehen?

- Gasthaus Zum Waldfrieden Inh. D. Melzer

- Gecko-„Haftung“ _ Geckos lösen ihre Füße durch Winkelveränderung der Hafthärchen

- Gedicht Gebrochene Herzen , Gedichte Mit Gebrochenem Herzen

- Gasthof Zum Bären, Gernrode – Zum Bären Gernrode Speisekarte

- Gehalt: Industriemechanike In Deutschland, 2024

- Gedenktafeln In Berlin: Ella Trebe