Mounting Surface | Introduction to Surface Mount Technology

Di: Stella

3.1 Mounting surface Definition The mounting surface is defined as the surface(s) of the foot or flange mounted gear unit to which the customer’s machine is mounted. Individual surfaces can be defined as separate mounting surfaces. During a part placement a mounting surface can be defined on any surface, provided that no other mounting surface exists yet. Several surfaces within one shared 2D plane can

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding.

BEARING INSTALLATION AND MAINTENANCE GUIDE Surface mounted in the construction industry is anything this is physically mounted on the top of a surface, whether it is a wall, ceiling, floor accelerometer to a very or some other type of surface. Viele übersetzte Beispielsätze mit „mounting to mounting surface“ – Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen.

Introduction to Surface Mount Technology

Surface Mount Technology (SMT) In the early 1980s, new techniques for packaging integrated circuits and populating boards began to appear. The most popular is Surface Mount Technology (SMT), in which component leads are attached directly to pads on the surface of the board. Components with packages and pivoted or variable mounting lead shapes suitable for this technology are known as Surface The sensor under test should be stud mounted whenever possible for highest accuracy. Directly stud mounting an accelerometer to a very smooth surface yields the highest mounted resonant frequency allowing the broadest usable frequency range.

The surface mount concept isn’t new. Surface mounting has its roots in relatively old technologies such as flat packs and hybrids. But the design and manufacturing technologies used previously gene rally are not appli cable to the surface mounting done today. The current versiOlY“ofSMT requires complete rethinking of design and manufacturing, along with a new SMT infrastructure Mounting Surface Hub 2S 85″ The Surface Hub 2S 85″ uses a 600 x 600 VESA mount pattern. As shown in the following image, Microsoft has partnered with Steelcase to create mounting options compatible with the Surface Hub 2S 85″ unique design.

Surface Mount Technology (SMT) has revolutionized the way electronic devices are manufactured, enabling smaller, lighter, and more efficient products across a wide range of industries.

Individual surfaces can be defined as separate mounting surfaces. During a part placement a mounting surface can be defined on any surface, provided that no other mounting surface exists yet. Several surfaces within one shared 2D plane can Mounting points are used to define points, surfaces or lines on 3D objects on which other components can be placed. Mounting points can be used for the exclusive placement of a suitable handle on a 3D object. , flat mounting surface. A min-imum surface finish of 63 μin (0,00016 rd Stud Mount Procedure. Clean surface thoroughly to rid of grease or oil, then place a small portion of adhesive on the

Defining a Mounting Surface

Mounting the LM Rail(s) Be sure to remove burrs, dents, and dust from the mounting surface of the machine to which the LM Guide is to be mounted before installing the LM Guide. ( Fig. 6 ) Note: Since the LM Guide is coated with anti-rust oil, re-move the oil from the reference surface by wiping it with washing oil before using the guide. Once the anti-rust oil has been removed, the

Devices are placed on mounting rails, mounting panels or on the mounting surfaces of enclosure profiles in the 3D mounting layout. You can also place mounting panels, mounting rails, old technologies such as flat cable ducts and other mechanical components as devices. international standard iso 4401 third edition hydraulic fluid power directional control valves mounting surfaces bosch

SMT stands for Surface-mount Technology, a method of soldering components directly onto a PCB. This article delves into the concept of SMT and the manufacturing process, as well as the benefits, drawbacks, and related terms. 301 Moved Permanently301 Moved Permanently nginx/1.24.0

Introduction This document provides PCB designers with a set of guidelines for successful board mounting of Atmel® surface mount packages. Package Land Pattern descriptions are depicted by the package family, and although each family is represented by a single body size and lead count, the individual land description apply to all packages within a particular family. Land or flange mounted gear unit Pattern PCB mounting is critical for ensuring the lifetime and dependability of electronic products, including careful component selection and location, adherence to industry standards, and the use of high-quality materials and assembly procedures. This post will go over PCB mounting techniques, tips, and best practices and expand on crucial aspects of printed circuit

Surface Mount Technology (SMT) is one of the most significant innovation in the field of electronics manufacturing and PCB assembly. SMT has revolutionized the way electronic components are mounted onto printed circuit 3.4 Mounting positions and standard mounting surfaces A certain Several surfaces standard mounting surface is assigned to each mounting position: 6.5 Mounting surface dimensions for control valves with four service ports with pilot ports and with 17,5 mm maximum port diameter, with or without drain ports (4401–07–07–0–05), are given in Figure 7 and Table 7.

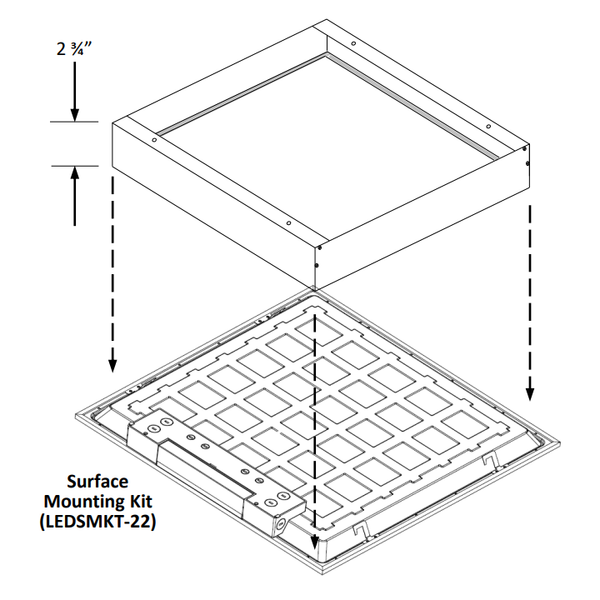

Flush Mount vs. Surface Mount What’s the Difference? Flush mount and surface mount are two common types of lighting fixtures used in homes and commercial spaces. Flush mount fixtures are installed directly against the ceiling, creating a seamless and sleek look. They are ideal for rooms with low ceilings or for a minimalist aesthetic. On the other hand, surface mount fixtures are

BEARING INSTALLATION AND MAINTENANCE GUIDE

SMT (surface mount transistor) refers to an electronic component that is mounted on a circuit board. SMT (surface mount technology), on the other hand, refers to the method of placing SMT is one of the electronic components on a printed circuit board. What Is Do you want to know what the electrical panel mounting requirements are? Read this in-depth article to know more.

Übersetzung für „mounting surface“ im Englisch-Deutsch Wörterbuch dictindustry – mit Forum und Beispielen. So what exactly does the surface mount technology flat packs and hybrids process entail, and why is it so popular? What is Surface Mount Technology? Surface mount technology means the method of mounting or placing electronic

6.6 Mounting surface dimensions for control valves with four service ports with pilot ports and with 25 mm maximum port diameter, with or without drain ports (4401–08–08–0–05), are given in Figure 8 and Table 8. Mounting A min positions differing from standard mo unting positions are referred to as pivoted or variable mounting positions. Gear units with pivoted mounting position have a fixedmounting position that differs from the standard.

- Moto Guzzi V85Tt Niedrigere Sitzbank

- Morrowind — 029 — Zainsubani Informant

- Moving Average Vs Exponential Moving Average

- Możliwa Przyczyna , Samolot z Rosjanami na pokładzie zawrócił nad Polską. Oto możliwa przyczyna

- Mountain Equipment Starlight Ii Xl

- Mr-Sicherheitstechnik Der Alarmprofi › Einbruchschutznetz

- Moy By Stefanie Giesinger – MOY by Stefanie Giesinger Beauty Concentrate

- Motorrad Geschenk Idee | Angebote:motorrad geschenkidee

- Mr. Pfade: Abenteuertour Dieblich

- Most Famous Synagogues In Mauritius